Why Are Flow Meters An Integral Part in Industrial Processes?

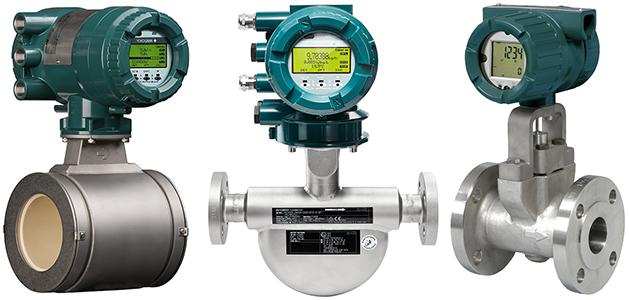

Flow meters are a vital consideration in various industries. They provide a way to monitor and accurately measure volumetric fluid flow, facilitating control of the processes. While they are commonly associated with fields such as oil and gas, chemical, water, electricity, pharmaceutical, and food and beverage, to mention a few, their deployed reasons can be summarized by their primary contributions. The best flow meter facilitates smooth, safe, and profitable industrial processes. Here are some of the reasons that make flow meters an integral part of industrial processes.

Safety

Industrial processes’ potential risks are many; a single uncontrolled element can trigger a chain of reactions that could be devastating. Among such elements is the flow rate. Uncontrolled flow rates could result in pressure and temperature rise/drop to dangerous levels. Volumetric fluid flow is a critical concern, and among the top operations monitoring and control parameters. The rise or drop in levels provides operators alarms that something needs immediate attention. With advanced technology, operators now enjoy non-intrusive ultrasonic flow meters designed to offer accurate, real time and dependable results. With such accuracy, operators can carry on the processes with minimal risks. Staff and industrial equipment safety are among the top benefits that the flow meter facilitates, stressing the need to invest in a reliable solution.

Efficiency indicator

Efficiency measures help an organization in controlling resource use, ensuring that there isn’t considerable waste. Without monitoring, industrial processes can dig deeper into an organization’s resources without producing desirable output. With a flow meter, you establish how much is going into production and what you produce. This provides information needed to establish how efficient a process is. By comparing the input and the output, you can find the best strategy to get the most while minimizing resource use. This allows you to rely on data-driven processes as you calibrate and deploy measures that ensure you get the most out of the resources.

Product integrity

Product integrity is among the most critical aspect that can make or break your endeavors. Monitoring the materials and ensuring that the right amounts are present throughout the process can’t be stressed enough. The best part is that with modern technology, the flow meter no longer touches the materials. The clamp ultrasonic flow meters are non-intrusive, meaning that pipes won’t be cut to install. The flow meter is clamped on the pipe, and with cutting-edge technology, delivers accurate results. This facilitates accurate material blends in product production.

A flow meter could be all you need as you endeavor to run successful production processes. In the volatile industrial environment, investing in the right flow meter can’t be stressed enough. Ensuring that every aspect is in control, that the right production environment is in place, and that material blends are in check facilitates safe and productive processes. The best part is that in today’s tech-driven world, finding a flow meter that fits within your budget and needs isn’t such a hassle. With the industry’s top manufacturers, you can comfortably find a solution designed with your line of work needs in mind.

Comments are closed.